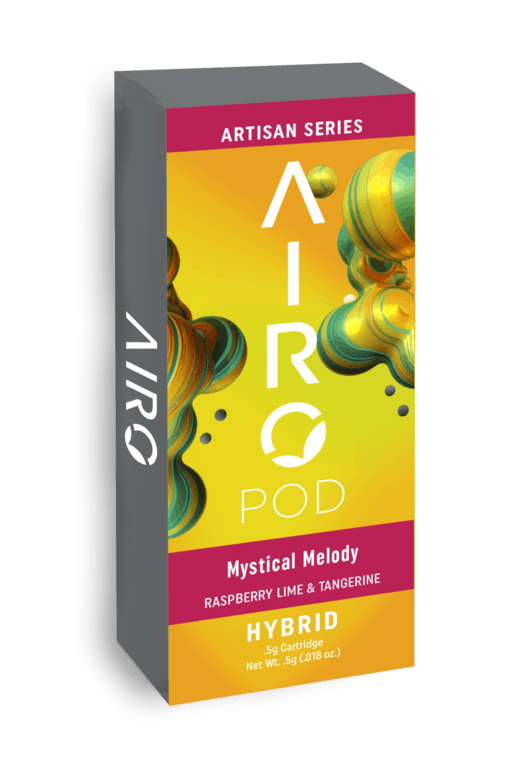

Harvested and Frozen in less than two hours captures the natural plant essence. Ensuring that the plant never thaws out after it is frozen keeps it fresh also known as “live” for processing. Pretesting is done with certified labs to ensure we start with only the best ingredients. our Cryogenic temperatures are utilized during extraction enabling the liquid butane running through the biomass to pull out the natural spirit that each strain has to offer giving you the best experience possible. Pressures and temperatures are closely monitored during the process enabling us to consistently provide light beautiful oil to our finishing experts. Changing the liquid solvent mixes can also help us to match the strain and profile we are trying to capture. Cold filter, dewaxing and ultra-refining can be implemented during the process to prepare the oil for specialized finishes. Our attention to the small details produces a fresh oil with the smell, color and texture ready for the finest kitchen. The proprietary finishing process starts with pressure, heat, love, patience and ends with our sommelier’s concentrate that would please any connoisseur.